Building secure IoT solutions for manufacturing

IoT connectivity offers numerous benefits for industry and manufacturing, including improved efficiency, productivity, quality control, safety, and cost savings.

As businesses continue to adopt this technology, we can expect to see even more innovations and advancements in the manufacturing sector in the years to come.

Sparking innovation for Industry & Manufacturing

IoT connectivity allows for the seamless integration of devices and equipment, enabling real-time data monitoring, analysis, and control. Here are some of the key benefits of IoT connectivity for industry and manufacturing.

Improved efficiency

IoT connectivity allows manufacturers to monitor and control various processes in real-time, leading to improved efficiency and productivity. For example, IoT sensors can be used to track the performance of machines, identify potential issues before they occur, and even trigger maintenance processes automatically.

Reduced downtime

By monitoring equipment in real-time, IoT connectivity enables businesses to detect and address issues quickly, reducing downtime and preventing costly production delays.

Enhanced quality control

IoT connectivity enables manufacturers to collect real-time data on the production process, allowing them to identify defects and quality issues before they become major problems. This can help businesses maintain high levels of quality control and reduce waste.

Increased safety

IoT sensors can be used to monitor working conditions, such as temperature, humidity, and air quality, to ensure a safe working environment for employees. In addition, IoT connectivity can be used to track the location of employees and equipment, improving safety and security in the workplace.

Cost savings

IoT connectivity supports businesses saving money by reducing waste, optimizing energy consumption, and improving overall efficiency. By identifying and addressing inefficiencies in the production process, businesses can reduce costs and increase profitability.

Teltonika RUT241 Industrial 4G Router with Com4 eSIM Connectivity

A compact, industrial-grade router combining Teltonika’s proven reliability with Com4’s global eSIM connectivity for fast, secure, and scalable IoT deployments.

Preloaded with Com4’s eSIM profile, the RUT241 delivers instant connectivity out of the box — no physical SIM required. Ideal for industrial IoT and M2M applications across Europe and beyond, offering flexible management through Teltonika RMS and Com4’s connectivity platform.

You’ll get:

● A quick assessment of your use case and connectivity needs.

● Guidance on RUT241 setup, RMS, VPN, and eSIM profile management.

Helping Industry & Manufacturing scaling to success

Our work in the manufacturing industry is expanding from facilitating connectivity in factories to enabling seamless connectivity of OEM products before they are shipped. Through Com4´s vast selection of mobile networks, our clients have the flexibility to connect their applications and products to the most suitable network based on availability, data usage, and contract length.

Additionally, for mobile applications, roaming SIMs are available with the option to choose the strongest signal.

Multi-IMSI and eSIM technologies

In addition to our cellular IoT connectivity, we are now exploring the use of Multi-IMSI and eSIM technologies. This will be a game-changer for OEMs, as their end-products will be equipped with embedded technology, ready for commissioning upon use.

We are continuously integrating routers and support services into our end-to-end enterprise solutions, ensuring seamless connectivity and plug-and-play pre-configuration for applications to be fully operational from the first day.

Customer Cases

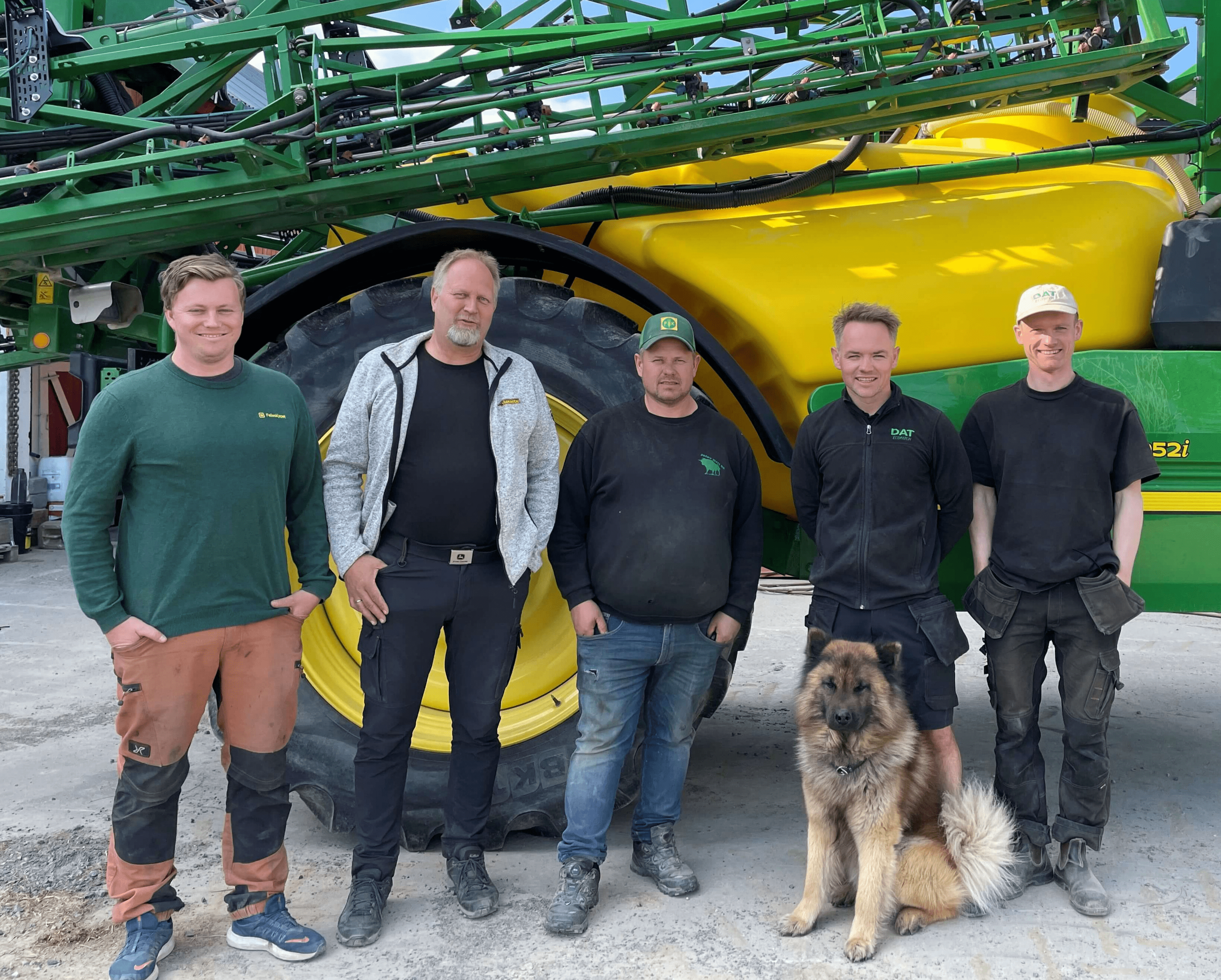

With Com4 IoT connectivity and AI, farmers achieve higher yields using fewer chemicals

Learn how Dimensions Agri Technologies uses Com4 IoT connectivity and AI to give farmers precise weed control, reduce chemical use, and increase crop yields across Europe.

MedThings empowers healthcare – with design, data-driven medication, and eSIM from Com4

MedThings offers a Norwegian digital medication solution with smart sensors, sleek design, and Com4 eSIM—enabling real-time dosing, remote updates, and seamless healthcare integration.

Construction site security – in real time

Intellity has developed an advanced camera solution that drives away intruders in less than two minutes. This solution helps prevent the security risks that plague the construction industry.

Beehive's technology and Com4's IoT communication ensure safer kindergarten trips

More time for play and learning for the little ones. More robust security when the kindergarten is on a trip. Less stress for the kindergarten staff.

Revolutionizing Electric Grid Maintenance: Gomero's Integration of IoT and AI for Enhanced Reliability

By using Gomero’s established and secure Infrastructure, along with cellular connectivity from Com4, more than 100 companies in 9 countries collect and analyze vast amounts of real-time data to make maintenance smarter.

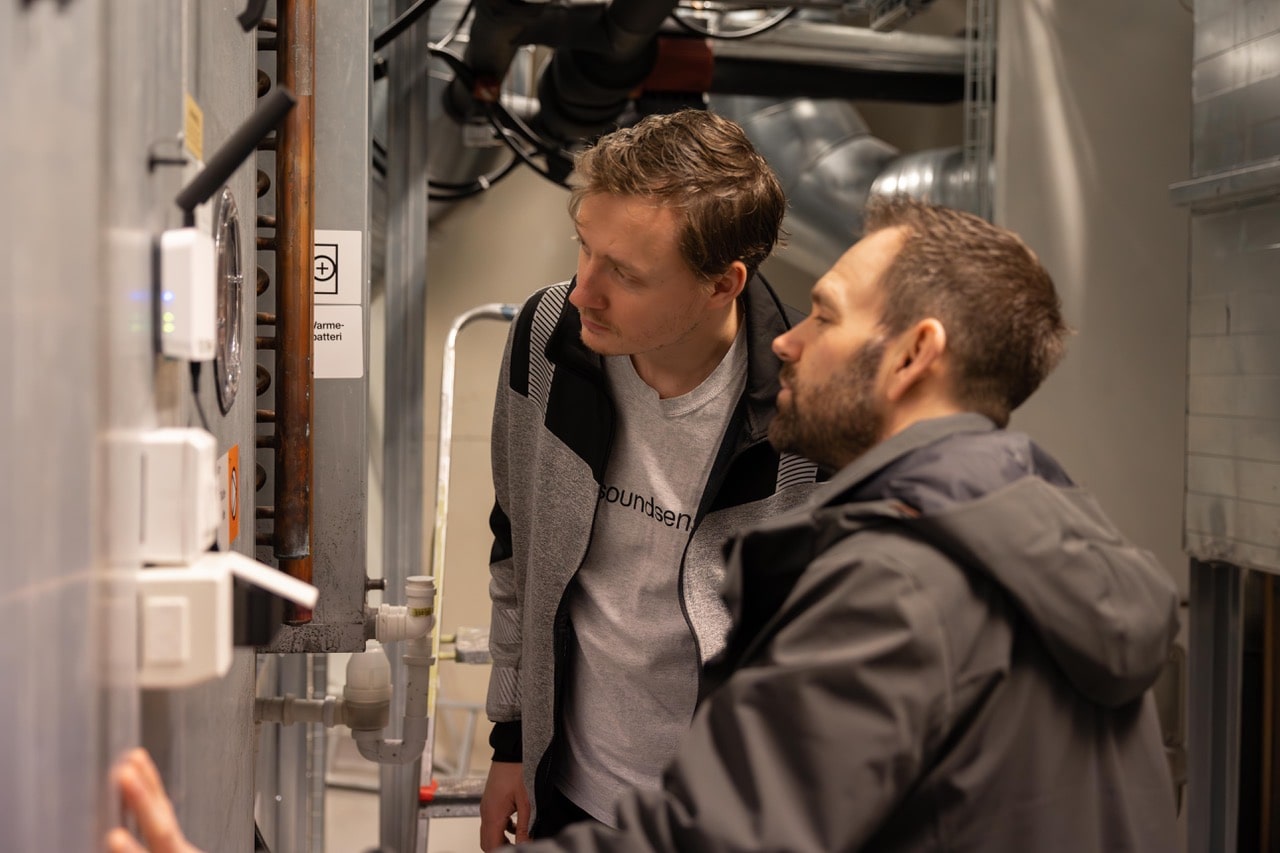

Soundsensing: IoT-Powered Noise Monitoring for Preventive Maintenance

A business idea based on noise. Sensors that hear when machines need maintenance and repair – before they break down. And an app that notifies the property owner. That's Soundsensing in a nutshell.

Let us help you creating robust industry 4.0 solutions.

Our Industry & Manufacturing experts are here to assist you.

CASE STUDY

CASE STUDY